Project Description:

From a purely chemical perspective, functional sugars refer to a category of substances including functional oligosaccharides, functional dietary fibers, and functional sugar alcohols, all of which have special physiological effects. Based on the characteristics of functional sugars and the results of our company’s experiments, we have selected the design of a fluidized bed granulation and drying machine to complete the granulation and drying process for functional sugars.

Material Description:

From a purely chemical standpoint, functional sugars encompass functional oligosaccharides, functional dietary fibers, and functional sugar alcohols, all of which have specific physiological benefits. Functional sugars include functional oligosaccharides, functional dietary fibers, and functional sugar alcohols. Among these, functional oligosaccharides are a type of functional sugar that has a beneficial effect on human health. They are typically low-degree polymeric sugars formed by 2 to 10 monosaccharides connected by glycosidic bonds into linear or branched chains. Not all oligosaccharides qualify as functional sugars; only those that are not digested or absorbed in the human gastrointestinal tract but are utilized directly by bifidobacteria in the large intestine are considered functional sugars. Due to the absence of enzymes in the human gut that can hydrolyze these oligosaccharides (except isomaltooligosaccharides), they pass directly into the large intestine. This characteristic allows them to be preferentially utilized by bifidobacteria, serving as prebiotics that promote the growth of beneficial gut bacteria.

These functional sugars mainly include: xylo-oligosaccharides, fructo-oligosaccharides, isomaltooligosaccharides, galacto-oligosaccharides, and soybean oligosaccharides. Functional sugars are often derived from materials rich in hemicellulose such as corn cobs, sugarcane bagasse, and wheat straw, using acid, acid enzyme, or enzyme methods, like xylo-oligosaccharides. They can also be derived from certain starch sugars using similar methods, such as isomaltooligosaccharides. Functional sugars are a relatively new concept that was first introduced to China from Japan and has received strong support and promotion from the government.

Equipment Overview:

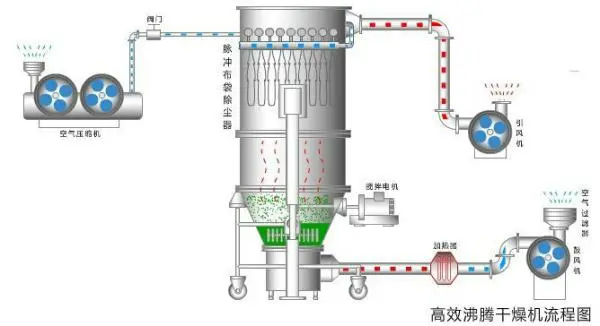

The FL Series Fluidized Bed Granulator, also known as a “One-Step Granulator,” employs a granulation method that combines spray and fluidized bed technologies. It utilizes high-speed hot air flow to fluidize powders and then uses the adhesive action of atomized binders to bridge and agglomerate solid powders, gradually forming granules. This machine is based on the traditional double-column gas-top granulator but is a newly developed single-column air-bag-sealed granulator.

Working Principle:

Powdered materials for granulation are placed into the fluidized bed. The powder particles undergo a circular fluidization in the material container, where they are preheated and mixed by purified heated air. An adhesive solution is atomized and sprayed in, causing some particles to cluster into granules containing the adhesive. As the hot air continuously dries the material, moisture evaporates from the granules, and the adhesive solidifies. This process repeats, resulting in the formation of ideal, uniform, micro-porous spherical granules.