As is well known, precursors are crucial for the production of ternary materials because the quality of the precursors (such as morphology, particle size, particle size distribution, specific surface area, impurity content, and tap density) directly determines the physicochemical properties of the final sintered products. It can be said that 60% of the technical content of ternary materials lies in the precursor process. Domestic ternary material manufacturers still have a certain gap in technology and production capacity compared to companies like Umicore in Japan and South Korea. Precursors occupy an important position in the ternary material industry chain, have high technical barriers, and significantly influence the quality of ternary materials. Moreover, they are non-standard customized products. Therefore, manufacturers that produce their own precursors have a competitive advantage in the race for technological upgrades.

With the rapid development of global new energy and new materials, new battery materials used in the widely applicable battery field have become an emerging sector that is set to grow rapidly in the coming years. This production process urgently requires revolutionary auxiliary equipment. In response to the specific characteristics of battery (electromagnetic) materials (such as ternary materials), we have developed specialized drying equipment for battery materials.

Ternary Materials (Ternary): The international authoritative dictionary Merriam-Webster defines "ternary" as "having three elements, parts, or divisions or arranged in threes." Therefore, "ternary materials" refer to materials composed of three chemical components (elements), constituents (simple substances and compounds), or parts (components), including alloys, inorganic non-metallic materials, organic materials, and polymer composite materials. They are widely used in mineral extraction, metal smelting, material processing, and new energy industries.

Cathode Materials:

Ternary materials include lithium cobalt oxide (LiCoO2) and lithium nickel cobalt manganese oxide (Li(NiCoMn)O2). The precursor products for ternary composite cathode materials use nickel salts, cobalt salts, and manganese salts as raw materials. The ratio of nickel, cobalt, and manganese can be adjusted according to actual needs. Compared to lithium cobalt oxide batteries, ternary material batteries are safer but have lower voltage platforms. For instance, when used in mobile phones (which typically have a cutoff voltage around 3.4V), there can be a noticeable lack of capacity. Some low-cost phones already use ternary material batteries, especially those with higher capacities. Lithium iron phosphate batteries, on the other hand, have lower capacity output and are not suitable for high-capacity mobile phone battery requirements.

Anode Materials:

Lithium-ion battery anode materials, such as "Silicon Nanowire/Super-P/Polyaniline" and "Silicon Nanoparticles/Carbon Nanotubes/Polypyrrole," are ternary anode composite materials. In June 2013, *Nano Letters* published an article titled "Three-Dimensional Hierarchical Ternary Nanostructures for High-Performance Li-Ion Battery Anodes," which used P-polypyrrole-coated silicon nanoparticles and single-walled carbon nanotubes as electrical enhancers. This significantly improved the electrochemical cycling stability and rate performance. Additionally, the low cost, high efficiency, and good compatibility with industrial processes have garnered widespread attention.

Project Description:

The disc dryer chosen for the ternary material precursor is a high-efficiency conductive continuous drying equipment. Its unique structure and working principle give it high thermal efficiency, low energy consumption, small footprint, simple configuration, easy operation and control, and good operating environment. It is widely used in the drying operations of the chemical, pharmaceutical, pesticide, food, feed, and agricultural and sideline product processing industries, and has been highly praised in practical applications. Currently, it is produced in three types: atmospheric, sealed, and vacuum, with four specifications: 1200, 1500, 2200, and 3000. Materials include S (carbon steel), B (contact parts made of stainless steel), and C (based on B, with added steam pipelines, main shaft and support made of stainless steel, and stainless steel lining for the cylinder and top cover). These three materials and drying areas ranging from 4 to 180 square meters result in hundreds of models, along with auxiliary equipment to meet users' drying needs for various materials.

Engineering Principles:

The PLG series disc continuous dryer features a structure where rake arms with rake blades perform rotational movements on the first layer of the drying disc, continuously turning the material. The material flows over the drying disc surface along an exponential spiral line. On small drying discs, the material moves to the outer edge and falls to the outer edge of the large drying disc below. On large drying discs, the material moves inward and falls through the middle into the next small drying disc. This alternating arrangement of large and small drying discs allows the material to continuously flow through the entire dryer. A heating medium passes through the hollow drying discs, entering from one end and exiting from the other. The dried material falls to the bottom layer of the shell from the last drying disc and is moved by the rake blades to the discharge port for ejection. The evaporated water vapor is expelled through the top vent, with entrained dust recovered by a pulse dust collector, and the exhaust gases discharged outside by a vent fan. The dry material discharged from the bottom can be directly packaged.

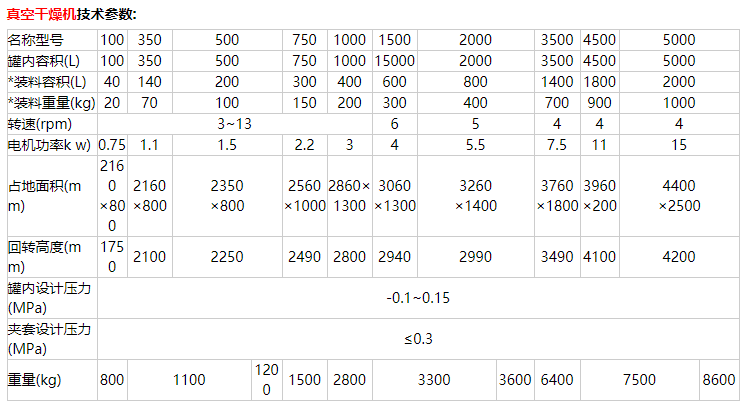

三元前驱双锥回转真空干燥机技术参数:

内胆容积 1000L,装料系数50,罐内真空度-0.098MPa.

2热水加热,工作温度100;按常压容器规范设计、制作。

3、夹套水压试验压力 0.5MPa,提供水压试验报告.

配备防爆型电机及变频调速控制箱,罐体转速 05rpm 可调4

5、机架及容器外包 SUS304 不锈钢镜面板符合 GMP 要求

6、304 材质真空管、真空头,真空头形式为三个真空头静密封结构。真空头与罐体同步运转,杜绝物料二次污染。

三元前驱双锥回转真空干燥机技术配置

锥体内胆、夹套及外包材料厚度。

罐体法兰 DN350 法兰、DN200 快开式卡箍304 材质。

内胆材料 304 8=8mm,提供材料质保书复印件。(欧钢或宝钢)。

夹套材料 Q235-B 8=6mm,提供材料质保书复印件。

(欧钢或宝钢)容器外包 SUS304 不锈钢镜面板8=2mm,提供材料质保书复印件。